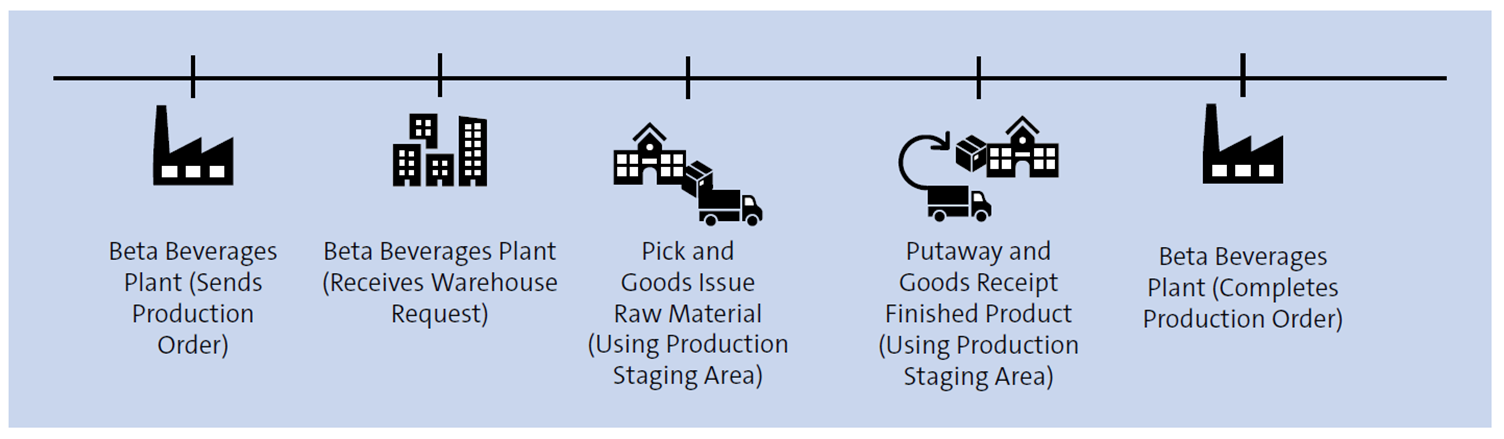

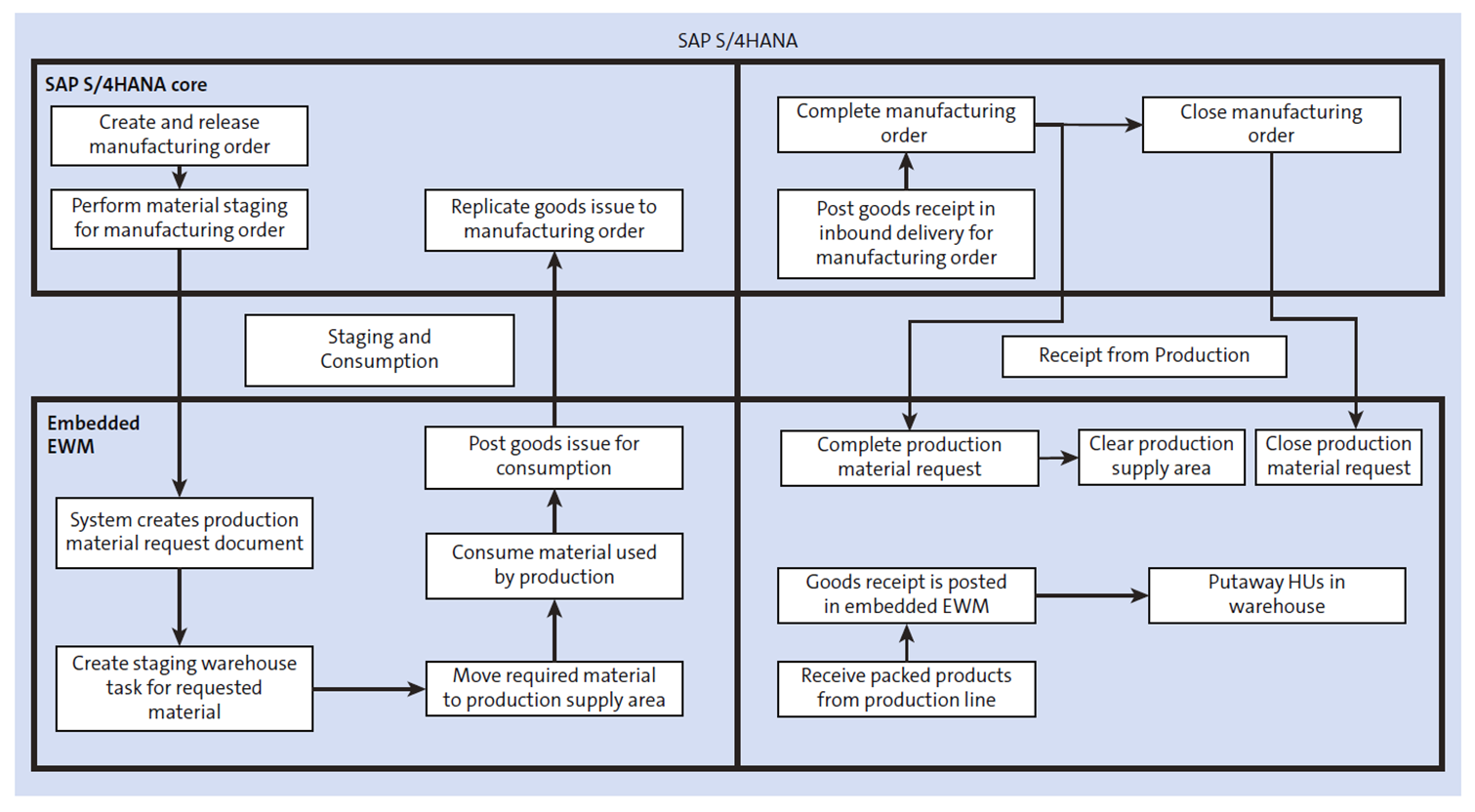

Advanced production integration helps streamline the manufacturing process for both production orders and process orders created in SAP S/4HANA. Production integration in embedded EWM enables staging of raw materials for manufacturing orders in the production supply area and receiving of finished goods against the order. You can use the following production processes for advanced production integration in embedded EWM: Advanced production integration allows for consolidated staging of products for production, which prompts optimal utilization of space in a production supply area. Packed products can be received manually or via radio frequency-based (RF-based) terminals after production is complete. The inventory for raw materials and finished goods is kept in separate storage locations in the warehouse, thereby improving inventory visibility in both embedded EWM and SAP S/4HANA. Along with the issue and receipt of materials for production processes, you can also integrate the production process with quality inspections for products being received in the warehouse. In the first section of this blog post, we explain the business context in which advanced production integration can be used in real-world scenarios. In the second section, we explain the processes carried out in the system and documents related to advanced production integration. American company Beta Beverages regularly manufactures multiple drinks that require its plants to supply raw materials to the nearly connected plants and receive finished and packed products from the plants via automated belts. This is initiated in SAP S/4HANA using a planned production order created as part of production planning (PP). The production order contains the information about required raw materials and finished products to be received from the plant to the warehouse. The raw material is to be picked from source bins by warehouse workers and moved to staging bins so that it can be sent to the plants via goods issue. Similarly, the finished products need to be received in the production bins and moved on to the destination bin in embedded EWM. As shown in the figure below, advanced production integration involves the following steps: The next figure shows an end-to-end flow for the production process in embedded EWM. The production process in embedded EWM can be split into two parts. The first step is staging and consumption, which entails staging raw materials in the production supply area and posting their consumption after they’re used in the production process. The next step is receiving, in which finished goods are received for storage in the warehouse. For example, a beverage-manufacturing company will stage multiple raw materials, such as sugar syrup, concentrate, and so on, in the production staging area near the production line from where the products will be consumed for production. Based on the production schedule of the beverage, PP in SAP S/4HANA creates a production order to demand components at the production line. After the production order is created and released in SAP S/4HANA, a production material request is created in embedded EWM. The production material request contains information about the raw materials and quantities required to produce the finished product (e.g., the beverage) on the production line. Staging components at the production supply area can be planned over a period based on the time required to supply the components to the production line. Based on requirements, the components are moved to the staging area using staging warehouse tasks, which are confirmed after staging is completed. After components are consumed by the production process, a goods issue is posted for the components, which updates both the production material request in embedded EWM and the production order in SAP S/4HANA. The finished products from the assembly line usually are packed in pallets (in HUs) before they are stored in the warehouse. Thus, when the beverage bottles are received in the warehouse, they’re packed in pallets, labels are printed and scanned, and a goods receipt is posted for the products in embedded EWM. Warehouse tasks for putaway are created and confirmed. The goods receipt is communicated to SAP S/4HANA, in which the inventory of finished goods is increased. The status of the manufacturing order in SAP S/4HANA is set to Technically Complete. This sets the production material request in embedded EWM to the Complete status. The production supply area is cleared, and unused materials are moved back into the warehouse. The manufacturing order in SAP S/4HANA is set to Closed, which sends an update to embedded EWM and closes the production material request as well. Tip: Any updates made in the production order in SAP S/4HANA are communicated to embedded EWM, and the production material request is updated synchronously. When the status of the production order is set to Technically Complete, components can no longer be staged, but consumption, reverse consumption, and production supply area clearing off can be achieved. When the status is set to Complete, no further action on the production material request can be performed. Editor’s note: This post has been adapted from a section of the book Warehouse Management with SAP S/4HANA by Namita Sachan and Aman Jain.

Business Process

System Process

English (US) ·

English (US) ·